Relius Medical sees sales grow by $3M!

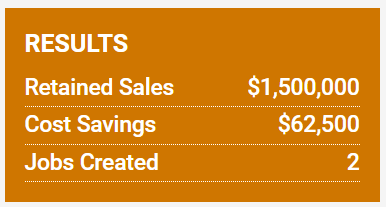

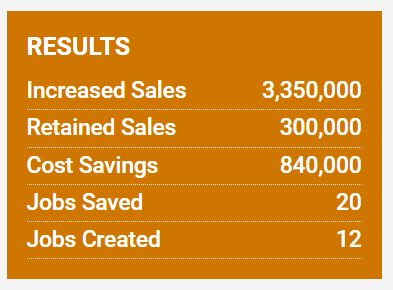

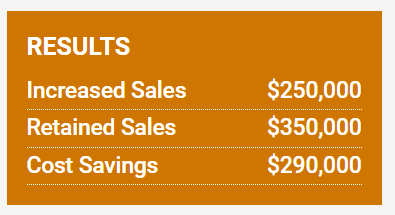

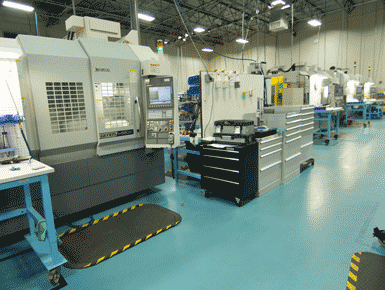

Relius Medical LLC, has been a real success story. BtenConsulting was brought in to help Relius improve their processes and skills of the team members. As a medical manufacturer, the paperwork accompanying the products are extremely important; without the proper certification the surgeon can not use the product shipped. BtenConsulting helped streamline and update the document control process. Along with other local partners like Pikes Peak Community College, BtenConsulting trained the workforce on Lean Principles and implemented many of the principles on the shop floor along with helping the leadership with Leading Lean. As a result, Relius saw $3M of increased sales and retained an additional $1M of sales that were at risk.

Additional details are at https://www.manufacturersedge.com/success-story/getting-their-edge-relius-medical-llc-sharpens-staff-with-manufacturers-edge-assistance/

Relius Medical LLC is now part of Eptam Precision Machining Solutions.